Click to play

Over 20 years of technological accumulation,

with leading technology, excellent product

performance,

and supporting service systems,

has laid a solid foundation for future development

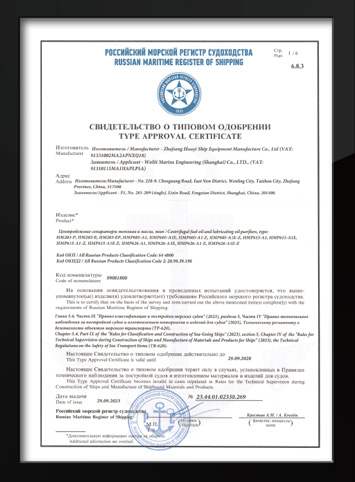

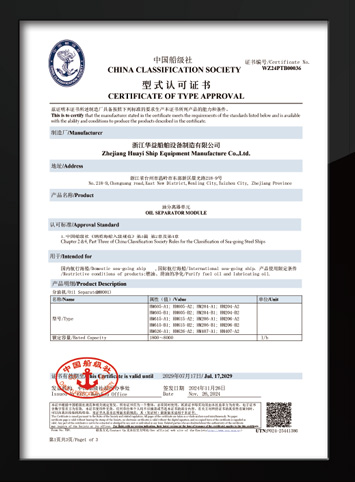

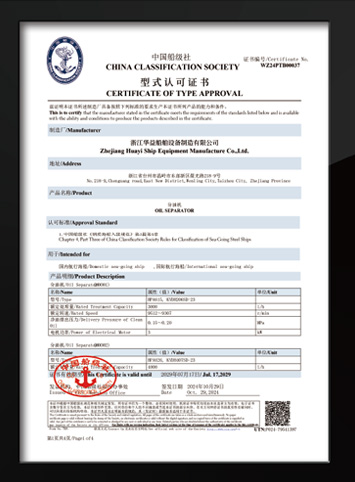

International authoritative certification:

Type approval from CCS, BV, RINA, KR, LR and other top ten global classification societies

System certification:

ISO 9001 quality management system.

The P series (specific gravity ring type) separator has been successfully developed, passed the 380cSt heavy oil durability test and classification society type approval, and has been launched into the market in batches.

With the advent of the intelligent era, the company adopts PLC control to upgrade the steps of slag discharge, sealing, and separation of the separator to automatic control, and achieves remote display through Profinet communication protocol.

Breaking through the separation technology of high-density oil products, the S series (extremely heavy ring form) separator has been developed, which has increased the separation density to 1100KG/m ³ and the separation capacity to 13300L/H (380cSt/50 ℃), and has been shipped for use.

According to the requirements of IACS (International Association of Classification Societies) Network Security E26&E27, we have applied for network security certification from various classification societies.

The first generation fuel supply unit has been launched, with core components including KRAL fuel pump, Aquametro viscosity meter&flow meter, German BollFilter filter, Swedish KRACHT pressure regulator and other international first-line brands, laying the foundation for product quality.

According to the requirements of the MARPOL Convention, develop fuel supply units that switch between heavy oil and low sulfur oil in different sea areas.

Realize full touch PLC intelligent control, one click switching of various oil products, adjustable temperature rise/fall speed, meeting international requirements for marine engine use.

The fuel supply unit can achieve remote display through Profinet communication protocol. According to the requirements of IACS (International Association of Classification Societies) network security E26&E27, it has applied for network security certification from various classification societies.

![]()

Separation efficiency ≥ 99.8%, MTBF (mean time between failures) exceeding 10000 hours;

![]()

Modular design reduces maintenance costs by 40%;

![]()

Fully comply with IMO 2020 sulfur limit regulations, EEDI energy efficiency standards, and MARPOL

Covering an area of 10000 square meters, equipped with fully automatic welding robots, high-precision fluid testing platforms, and a laboratory for simulating extreme working conditions

The annual production capacity of the oil separator is 1000 units, and the customized delivery cycle of the oil supply unit has been compressed to 60 days

Applying digital intelligent manufacturing technology to achieve full process traceability from raw materials to finished products

100% passed the 72 hour full load durability test, and the lifespan of core components is 1.5 times that of domestic competitors

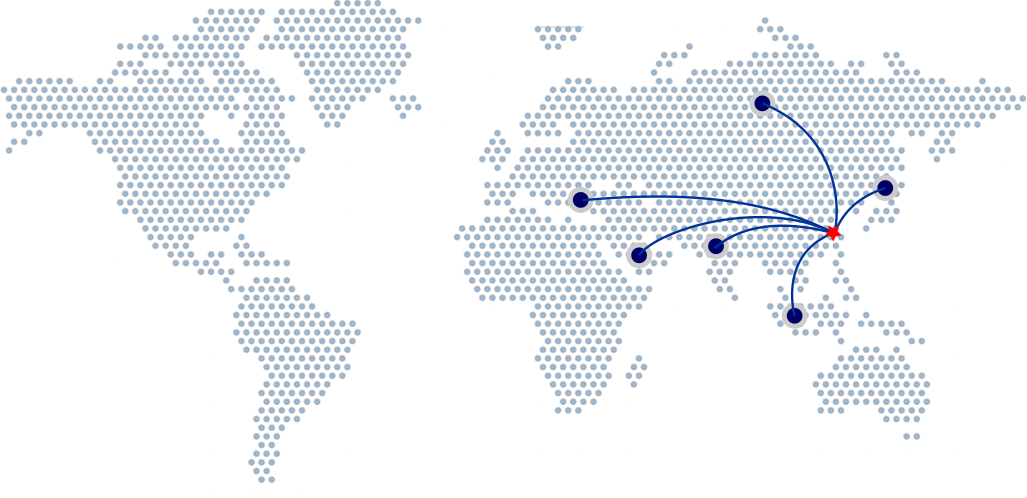

Covering core shipbuilding belts such as the Yangtze River Delta, Pearl River Delta, and Bohai Rim, with a commitment of 24-hour response and 48 hour on-site service;

Southeast Asia

Singapore Service Center

ARK VISION SPARE & ENGINEERING PTE LTD

51 Tuas Ave 1,Singapore 639501

51 Tuas Ave 1,Singapore 639501

+65 9616 5309 +65 6862 3379

+65 9616 5309 +65 6862 3379

arkvision@singnet.com.sg

arkvision@singnet.com.sg

Middle East

Dubai Service Center

MARITECH

WH-412,Dubai Maritime City

WH-412,Dubai Maritime City

+971 559565286

+971 559565286

rohil@maritech-solutions.com

rohil@maritech-solutions.com

Türkiye

Türkiye Service Center

YAF DIESEL SHIP SPARE PARTS LTD

0090 216 494 4902

0090 216 494 4902

yusuf@tmmarineparts.com

yusuf@tmmarineparts.com

Greece, Amsterdam, and others The service network is under construction .....